The ability to recognize modem alterations and outright forgeries is important to all students of archaeology. Consequently, in its training program the Near Eastern Section of the Museum has been actively concerned with building up a teaching collection of spurious as well as real antiquities. In 1967 we acquired a sword purportedly of late second—early first century B.C. from Iran, but suspected of being a ‘tampered with’ object.

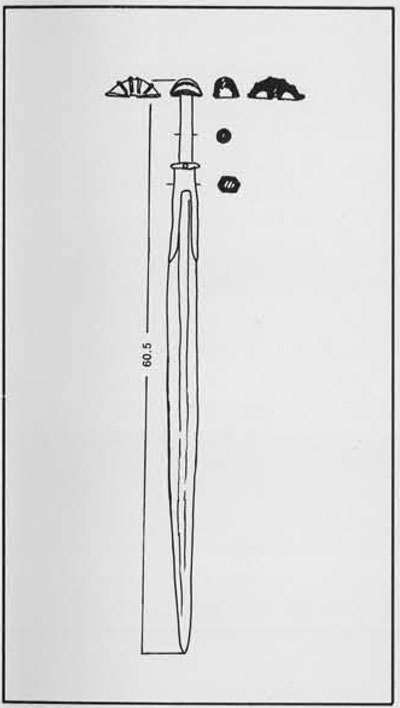

The sword, of bronze, was covered with straightforward and recognizable mineral alteration products. The corrosion on the hilt was smooth whereas that on the blade was more lumpy and included small spots of active ‘bronze disease.’ The hilt is cylindrical in section and terminates in a pommel with partially hollowed ‘wings.’ The pommel is decorated with small bands of a roughly herringbone pattern, the grip with incised lines, hatches, and chequers.

There are many typological and chronological points which can be debated, but without entering into a detailed discussion of these problems there are elements of design and technological refinement which render the piece suspect. For a more complete discussion of features of typology, functional refinement, and chronological development of Near Eastern armament, the reader is referred to the list of Suggested Reading.

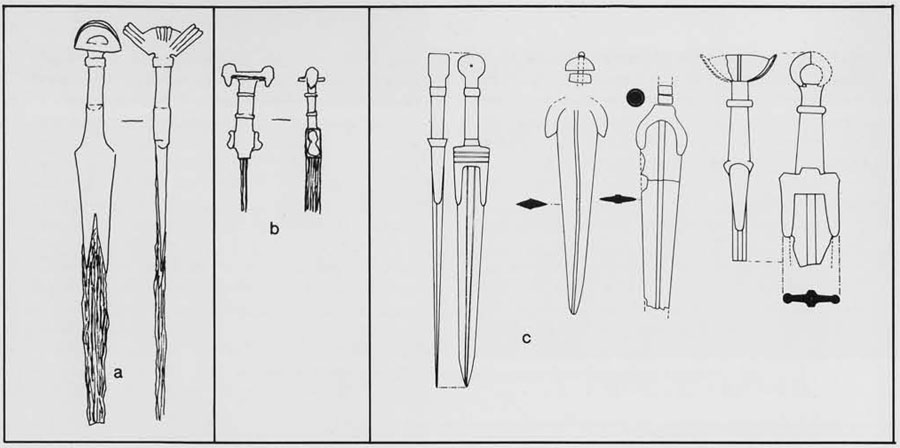

Briefly, where bronze blades with bronze hilts appear, they are usually joined in one of the following ways: 1) a tanged blade is riveted to the hilt and is often bound with an organic material, or the tang is of such length as to allow it to be bent over at the end, thus securing it to the hilt; 2) the blade and hilt are cast as one and the grip is then bound with some organic material; or 3) the hilt (usually) and certain details are ‘cast-on’ to the tanged blade, forming a virtually inseparable join which is usually distinguishable only by radiography (and then not always!) R. Maxwell-Hyslop and H. W. M, Hodges in an article in Iraq in 1964 reported that in the process of `casting-on’ the “blade and tang were first cast and the casting was then trimmed, hammered and polished. Subsequently a mould was prepared around the upper part of the blade and the tang, into which was paired the molten metal which would provide the handle of the dagger. After this second mould had been removed the handle would then be trimmed and polished.” In the same article they suggest that this method of joining blade and hilt is a late development which parallels or just precedes technology involving iron-working and is most often associated with the joining of iron blades to bronze hilts. Excavated examples of such types come from the 9th century B.C. levels of Hasanlu Tepe, Iran, being excavated by the University Museum.

The juxtaposition of pommel axis to blade axis is most often found in the later bronze examples; this also is associated with iron technology, most commonly with an iron hilt joined to an iron blade. The orientation in this manner is suggested as being most suitable for a ‘stabbing weapon’, as described by Ternbach.

Authenticated examples of design most resembling the University Museum weapon are of blades of iron attached to a bronze hilt. The object redrawn here from de Morgan from the Talish area in the Caucasus has a bronze ‘forked hilt’ gripping an iron blade. Presumably the blade is tanged and is thrust well up into the hilt.

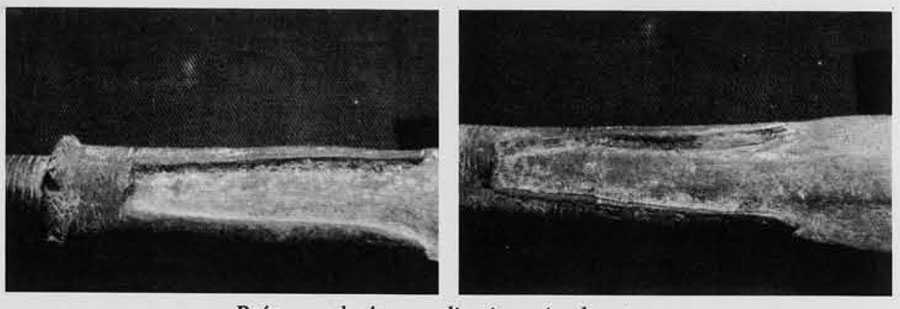

With these points in mind, we undertook some investigation of the critical areas of our suspect weapon. A radiograph was made through the kind assistance of Dr. Richard Chamberlain of the University Hospital. A print made from the X-ray film shows clearly that some very dense metal has been used between the tang of the blade and the hilt. Notable is the fact that the blade does not fit neatly into the hilt as one would expect from the degree of technological proficiency usually seen in examples of ‘cast-on’ hilts.

A magnet set against the grip, and even at the point of entry of the blade into the hilt, was attracted by considerable magnetic force. From the radiograph it is not possible to see what exactly is occurring within the hilt, but it is most likely that the tang is prevented from further insertion into the hilt by the presence of a considerable quantity of iron.

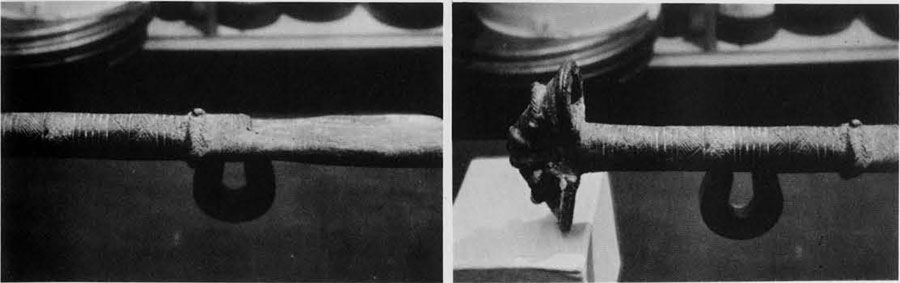

We then applied organic solvents to the area of join between the hilt and blade and not surprisingly the ‘corrosion’ in that immediate area began to dissolve. Microscopic examination revealed that, to simulate corrosion, a pigmented material mixed with a sand matrix had been applied — it should be admitted that the visual effect was rather convincing. Under the ‘soluble corrosion’ (in the areas revealed in the radiograph) a greyish bright soft metal began to appear. Under magnification we could see file marks where this grey metal had been filed back to give a smooth ‘cast together’ appearance. In some areas, one could poke through the ‘encrustation’ to reveal areas (seen in the radiograph) where the joining was not complete. There was definitely no ‘casting-on’ involved here. There is little doubt that the soft grey metal is a modern lead solder.

The shape of the blade can be roughly determined in the radiograph and from the areas revealed in the application of solvents. It is steeply shouldered and has a thickened mid-rib area which narrows toward the point. The tang, as seen in the radiograph, is fairly long. There is no indication of rivets along it. If present, these would probably show in the radiograph. What appears to be the broken end of the tang can be seen vaguely in the radiograph, but this cannot be verified without completely dismantling the object.

The evidence we now have indicates the blade could equally well be a lance, since steeply sloping shoulders are not characteristic of swords with long tangs, and this design does fit more easily with the spear and lance forms. The typological position of the blade is more difficult to trace.

Whatever the purpose of the blade once was, it does not belong to the present hilt. No doubt each is genuine but when put together they create a technological and esthetic monstrosity which fits nowhere in the Near Eastern typology of armaments. It is clear that the fit of the two parts is so bad that, even without the iron remains in the hilt, the tang could never be inserted into the hilt without forcing the side skirts further apart, causing a considerable damage and subsequent problems in covering up the damage. Consequently, the blade was only marginally inserted into the hilt and it was necessary to fill the gaps with wedges of lead solder. As a well-balanced weapon, the result is a failure. No self-respecting ancient Near Easterner would have used such a peculiar thing even if he had had lead solder to fit it together. However, at a cursory glance an unsuspecting buyer might well be tempted to purchase this object in ‘complete and good condition.’ Hopefully, the student of Near Eastern archaeology would look more closely.