Leaving aside such cases as inscriptions incised in stone or cast in bronze, almost all traditional writing in China, as well as a good deal of painting, has used the material known as Chinese ink. Although liquid forms exist, this ink has usually been made in sticks or cakes that may be rubbed with water on a slightly abrasive surface (the inkstone) to give the black fluid used by calligrapher, scribe, or artist.

Chinese ink has some antiquity. The earliest extant description of making it is in the Ch’i-min Yaoshu, an encyclopedic work of the 5th or 6th century A.D., and solid ink has been excavated from as early as the 3rd century B.C. Specimens from the Han and Chin periods have also been found, and writing in some version of black ink on silk, stone, bamboo, and wood goes back to the Spring and Autumn period (722 to 480 B.C.). From the 10th century A.D. onward, there are any number of accounts of ink and inkmaking. In recent times, studies of Chinese ink in Western languages have also been published; a recent comprehensive survey is that by Tsien and Needham (1985), which also cites the earlier works, and Franke (1962) is notable for translations of Chinese historical texts into German.

Despite this historical cornucopia, the origin and early history of Chinese ink remain obscure. The Ch’i-min Yao-shu description is similar in its essentials to those that came later, and though some details differ and experimentation apparently continued, the basic method of making ink had been defined by the 6th century. The material is a deceptively simple one, the only essential ingredients being carbon, in the form of soot or lampblack, and animal glue. However, all account stress the need for high quality in the starting materials and great diligence in mixing them. A pasty mass having a similar consistency to potter’s clay was made by adding the carbon to an aqueous solution of glue, and this mass was repeatedly pounded, rolled, steamed, sprinkled with water, and so forth. The necessity for repeated pounding was often stressed—the Ch’i-min Yao-shu suggested thirty thousand times, though this number was reduced in later texts—and it was clearly realized that the most careful mixing was necessary to obtain a good product. Portions of the mixture were pressed into wooden molds to form the sticks, which then had to be dried slowly and carefully. Cracking from a too rapid loss of water has been a perennial problem in inkmaking, and can easily happen to inksticks later if they are heated or exposed to drier conditions. Sticks have been formed into a variety of shapes, with designs or characters in molded relief, and have often been painted or gilded. Some typical ones are seen in Figure 1.

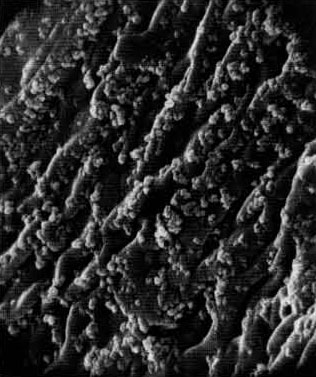

The earliest form of carbon was made by burning pine wood in a restricted supply of air and collecting the soot. Structures were devised to compel the soot (or some of it) to drift for a considerable distance before settling, and that which had drifted the farthest was considered to be of the highest quality. Such a procedure would separate the carbon from ash and tarry by-products, and ensure that the best ink, at least, was based on a pure, finely divided form of carbon. A later method of making the carbon (probably dating from some time after the 10th century, although the date is not certain) was to burn vegetable oil in a simple oil lamp and collect the lampblack so formed. In either case, the carbon was that formed in a sooting flame, consisting of minute, spherical particles often aggregated into clumps or chains. They are perhaps the finest particles among the pigments commonly used in East Asian painting (see Fig. 2). Certainly, other things were sometimes burned to make carbon—Yu Fei-an (1988) mentions lard and spoiled lacquer—but the desirable properties for inkmaking continued to be the same.

The glue medium was no less important (some accounts suggest that it was more important), and the quality of the glue governed in part the ratio of glue to carbon that could be used as low as 1:4 for the best qualities but often as high as 1:1. Most commonly, glue was made by heating bovine skins in water, but other animal products could be used. Deer antler (essentially the same material as bone) was recommended by some authors, and fish glues may sometimes have been employed. Animal glue, a protein, is an efficient dispersing agent and, when thoroughly mixed with the carbon, ensured that in good ink a fine dispersion was readily formed when the stick was rubbed with water.

Many other constituents have been added to ink from time to time, if the accounts are to be believed. Often, small amounts of a musk-like perfume have been incorporated, a custom that may have started as a way of disguising bacterial decomposition of the glue, but other materials are also cited, especially in the earlier texts. It is notable that, as time went on, the recipes tended more to avoid such additives and to stress the importance of the carbon and the glue.

Ink has long been made in Korea and Japan, as well as in China. Historical records state that it was introduced into Japan in A.D. 610. Presumably it was already known in Korea before then, but the date of introduction there is uncertain. Historical information from these countries is less available than from China, though both are known to have produced inks of high quality. The appreciation of good ink is a notable cultural feature in all three countries. Ink is expected to rub smoothly with water on the ink-stone to give an optically dense, black liquid (“each drop black as lacquer” is a metaphor sometimes encountered) that can be diluted to any desired shade of gray. The wide range of shades, coupled with the free-flowing character of the dispersion that affords a great flexibility when used with the Chinese brush, has allowed ink to be a most expressive medium in skilled hands.

The connoisseurship of ink has some odd byways, particularly when it comes to the subtleties of gauging quality. Some inks, for example, show a bluish overtone when diluted (the painting in Fig. 3 has this property) rather than being neutral gray or slightly brownish, and this has often been regarded as a characteristic of pine-soot ink (see Winter 1974).

Chinese ink has proved to be one of the more stable materials in East Asian painting. It is very lightfast, and the small particle size of the carbon coupled with good dispersion in the liquid usually leads to its penetrating the paper or silk sufficiently well to be mechanically stable. Figure 2 gives an impression of this from the way in which carbon particles have coated the surface of a paper fiber.