In his concise essay on the Urban Revolution, V. Gordon Childe listed the ten basic attributes of any complex, quantitatively and qualitatively, urban society. None of the ten attributes necessarily prevails over or is prior to any other as, according to Childe, the urban revolution is the end-product of a slow accumulation of expanding food surpluses and increasingly specialized technical know-how.

Almost a quarter of a century later the critics of Childe are now analyzing the complex system of cause and effect in which the various component elements of urban communities have been combined. Under the growing stimulus coming from anthropological categories the modern worker investigating the formative process of ancient Near Eastern civilizations is concerned with determining how demographic factors influenced economic factors, and how social phenomena were evoked by man’s gradual control over the productive potential of his environment.

Let us consider two of the points in Childe’s system. In his Point 2 he states that all cities included classes of persons who did not produce their own food—craftsmen, transportation workers, merchants—but were supported by the surplus produced by the peasants. In his Point 9 he says that another portion of the pooled surplus was used to pay for the importation of raw materials; he further states that regular foreign trade over quite long distances was a feature of all early civilizations.

Social differentiation stimulates the monumentality of religious worship, class specialization and the demand for highly-prized raw materials. Technological development favors an increase in work productivity and a corresponding increase in the demand for imported goods. This economic axiom is perfectly exemplified in the tremendous growth of Greater Mesopotamia between the end of the 4th and the mid-3rd millennium B.C.

The rapid socio-economic growth of Mesopotamia was a decided stimulus to trade with regions producing hardwoods, metals and semi-precious stones, the materials most in demand for the monumental temples of the Jemdet Nasr period and the lay courts of the Proto-dynastic period which followed.

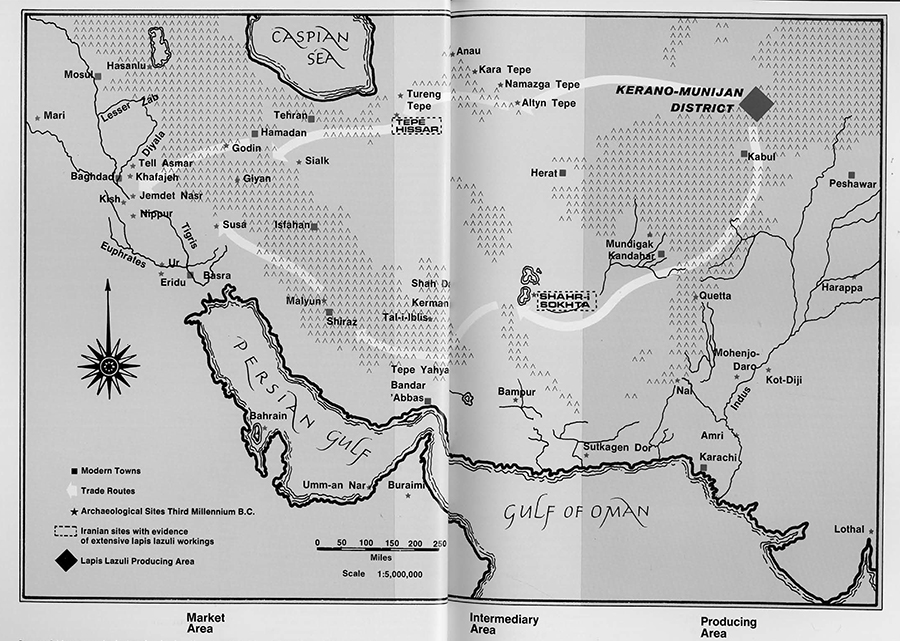

Lapis lazuli was one of the commodities in greatest demand for the decoration of temples and for personal adornment. In the Old World it is found in abundance on the southern shores of Lake Baikal and in the Kerano-Munjan district of Afghanistan. The metamorphic structure of the lapis lazuli found in Sumerian sites in Mesopotamia seems to indicate that it came from Afghanistan, over more than 1200 miles of rugged mountains and extensive desert areas.

As the Sumerians had no political control over either the production centers or the intermediate Iranian plateau, for a good half of the 3rd millennium B.C. these more or less constant supplies were guaranteed by independent centers situated on the plateau, which acted as middlemen in the trade. In any case, all commercial transactions are characterized by one or more intermediaries. The exchange value of the commodities is proof that they were no longer exchanged on the basis of a direct and strictly temporary evaluation but as a function of the usefulness of the exchange in itself. The merchant thus became a full-time worker who in turn might stimulate new productive and manufacturing activities in his community as a function of the exchange of goods, most of which may have been in transit.

Scholars realized the importance of these mediating centers as research work progressed in eastern Iran—this large, semi-arid region which, however, was not lacking in favorable environmental conditions and large concentrations of population. Erich Schmidt’s excavations at Tepe Hissar (1931-32) for the University Museum as well as those of the Soviet Academy of Sciences in southern Turkmenia and of the Istituto Italiano per it Medio ed Estremo Oriente at Shahr-i Sokhta have revealed the existence of technologically advanced towns and villages on the western slopes of the Afghanistan plateau.

In the strata corresponding to the period 3000-2000 B.C. in the larger settlements, in particular at Shahr-i Sokhta and Tepe Hissar, remarkably large quantities of chips, rejects and finished objects of lapis lazuli have been found side by side with equally large numbers of stone implements made of flint, jasper and touchstone.

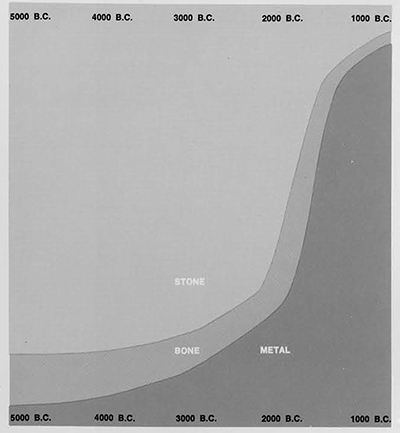

In the past, workers engaged in studying ancient urban civilizations paid relatively little attention to the lithic industry, absorbed as they were in the study of artistic and monumental products. And yet, according to the evidence at hand, it seems likely that, during the whole of the 3rd millennium, technology and economic production were still closely linked to stone implements. Whereas in Mesopotamia it may be claimed that these implements were rapidly replaced by metal ones, in Iran, Turkmenia and the Indus Valley many classes of implements were only slightly affected by the advent of metallurgy.

However, the evidence provided by the latest research seems to indicate that these classes were affected, as regards quantity and typology of the implements, by the gradual increase in trading. In the trading regions between the mining centers in Afghanistan and the Mesopotamian markets, the relationship between technology and trade is reversed with respect to Mesopotamia. Rather than technology stimulating trade, the latter affects the specialization of men and implements in the regions the product passes through.

This recent chapter in archaeological research in Iran has been documented not by sensational discoveries but by the application of two now long-standing methods: flotation of the excavated soil and functional analysis of the stone implements.

Functional analysis of the lithic industry has become one of the essential aspects of prehistoric research. Following on from the studies carried out by F. Bordes and S. A, Semenov, numerous scholars are now analyzing single classes of implements from this standpoint with a view to learning how individual artifacts were used by observing the microscopic traces left by their utilization.

However, little has so far been accomplished on material from protohistoric urban settlements in the Near and Middle East, although these sites are well suited to this kind of research.

In the first place, the state of preservation of the majority of finds from sites such as Shahr-i Sokhta often provides an immediate confirmation of the working hypotheses and of ten allows whole implements to be found and not just single components consisting of the lithic artifact.

Secondly, the possibility of directly relating the single classes of implements to the rest of the archaeological evidence found in the same room of a building or in restricted areas of the excavation site allows the immediate association of the implement to the object for which it was used, thus eliminating a source of uncertainty which is always present when the finds are palaeolithic or come from cave levels characterized by the superimposition of various activities in a relatively restricted area.

Thirdly, the chalcolithic industry of Shahr-i Sokhta appears to be characterized by a production background which is common to the whole population and is composed of such simple implements as blades, sickle blades, end-scrapers, and so forth, which were used in numerous different ways according to the daily activities. Grafted on to this is the highly specialized production, restricted to single groups of artisans, of extremely standardized implements used exclusively for working particular classes of objects such as stone seals and alabaster beads, or for the manufacture of certain highly prized materials such as lapis lazuli, turquoise and carnelian. This specialization, which also attests the presence of full-time artisans, results in the production of a large number of implements which are morphologically identical because, due to the technical skill of the artisan who makes and uses them, they are practically free from variations. These implements are usually concentrated in well-defined areas.

One of these areas, discovered during the 1972 excavation campaign in the northwest zone of Shahr-i Sokhta, consists of a center for the intensive working of lapis lazuli and, to a lesser extent, of carnelian and turquoise.

In the autumn of 1972, the excavation of the center and the flotation of all the earth fill in the excavated rooms allowed the recovery of a huge quantity of lapis lazuli waste and of a certain number of finished beads as well as beads broken during the various working phases, in close association with a good number of microlithic implements hitherto unreported among the material found on the surface or coming from excavations previously carried out in various zones of Shahr-i Sokhta.

Also, during the excavation of the necropolis, we had the good fortune again to find this association between lapis lazuli and stone implements in one of the most recent tombs discovered (G. 12). In another tomb (G. 10), a set of 28 microblades and a flint borer had been placed inside a bowl, and a similar offering of 99 microblades was contained in a pear-shaped beaker found in G. 2. All these tombs date to between 2600 and 2400 B.C. This group of finds allows the whole process of lapis lazuli working to be reconstructed and certain classes of stone implements to be assigned to the individual phases of the process.

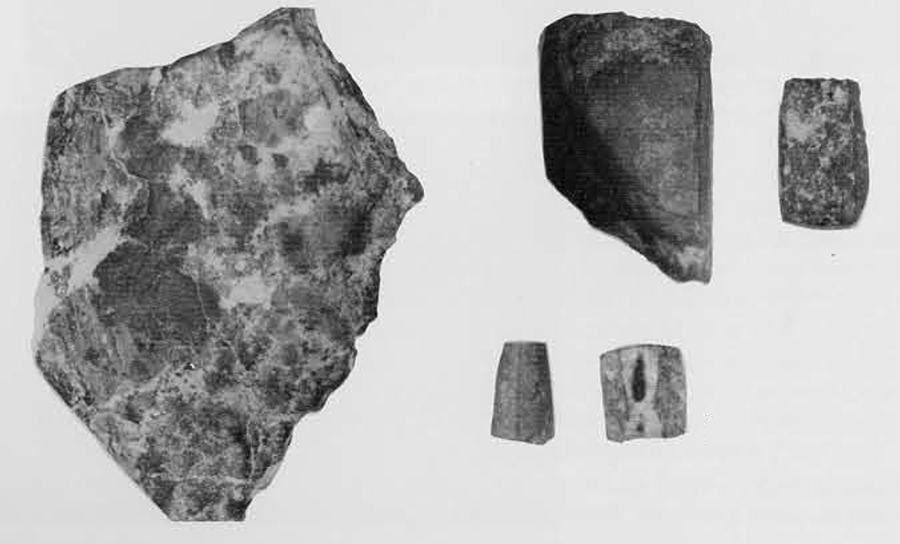

When examined under the microscope, a large number of lapis lazuli rejects revealed the presence of incisions, polished surfaces and chipping which are the tiny scars left by the artisan during the initial working phases of the raw material.

The lapis lazuli from Badakshan is found in large, rounded masses composed of a limestone cortex enclosing one or more zones of purer lazurite. It thus required an initial cleaning operation to separate the valuable material from the impurities accompanying it. For this purpose, a small portion of the surface of the mass was polished and an incision having an average depth of 1 mm. was made at the dividing line between the limestone and the lazurite, using a flint microblade with a trapezoidal or triangular section. Tests carried out on lapis lazuli waste using similar blades have shown that this was a fairly simple operation, the blade easy to use by hand and the incision made rather quickly. At the end of the operation faint traces of utilization are visible on the edges of the blade.

The separation of the purer material from the cortex was carried out by striking the block at the point of incision at a certain angle, probably using the indirect striker method which is well-known in stone-working.

The whole process may have been made easier by heating the blocks to soften the raw material. Evidence for this surmise is found in the signs of cracking and in the darker color of the surface of several small blocks of lapis lazuli.

By repeating these three operations of smoothing, incising and chipping on the lapis lazuli block, the rough shape of the desired bead was finally obtained. It was then finished by polishing the whole surface.

The results of these operations can be seen at Shahr-i Sokhta in the classification of the lapis lazuli wasters. The majority are flakes or blocks, followed by fragments with polished surfaces, others with the furrow left by the incision or with several furrows intersecting at the corners of the blocks, and others again with a more regular shape, almost completely polished and ready for drilling but still showing faint traces of the furrow.

The next working phase, drilling, must have been the most delicate of the whole process and the one in which the probability of wasting pure and extensively processed material was greatest. These losses are attested by the numerous partially perforated beads broken during drilling found among the lapis lazuli wasters. Indeed, in comparison with the number of wasters, very few finished beads were found in the excavation of this production center. Erroneous drilling angles and flaws in the crystalline structure were the main causes of failure.

The last phase was the polishing of the still rough surfaces of the fragment. In more recent times, this was carried out by putting a large number of already drilled beads in a damp leather bag which a laborer then kept rotating. The constant friction on all sides ensured the definitive smoothing and polishing of the beads. There is no direct evidence that this was the system in use but the lack of any implement suitable for polishing makes us at least suppose the existence of a similar process.

It must be remarked that this system of interlocking phases was not so rigid in the workshop excavated at Shahr-i Sokhta. In some cases, it appears that polishing preceded drilling, and that drilling could occur before smoothing. Besides, the presence of a large number of pyramid-shaped flakes seems to point to the existence of an alternative process to the one of cutting and hammering to separate the blocks.

The system of working lapis lazuli thus seems to consist of two important, quite distinct phases: a) the separation of the lapis lazuli from the mass of calcites and barylites which were technologically and economically worthless (basic working process); b) the production of objects from the purified lapis lazuli (specific production processes).

For technical reasons and perhaps also because of the existing system of division of labor, the basic process seems to have consisted of a rigidly fixed series of phases, while a certain amount of flexibility according to the day to day requirements of the workshop was allowed in the specific processes. We shall see later on the importance of this distinction in the system of trading between Mesopotamia and Badakshan.

In a report preceding the 1972 excavations on the microdrilling techniques connected with the production of stone seals and alabaster beads it was stated that the drill-heads used for these classes of objects could not have been the same as those used for drilling lapis lazuli and turquoise beads, mainly because the diameter of the holes visible in the latter (no greater than a millimeter and a half) was much smaller than that of the drill-heads (about 2-3 mm.).

Only by virtue of flotation was it in fact possible to find hundreds of tiny microlithic borers which, as we shall see later, were, closely related to the production of lapis lazuli beads.

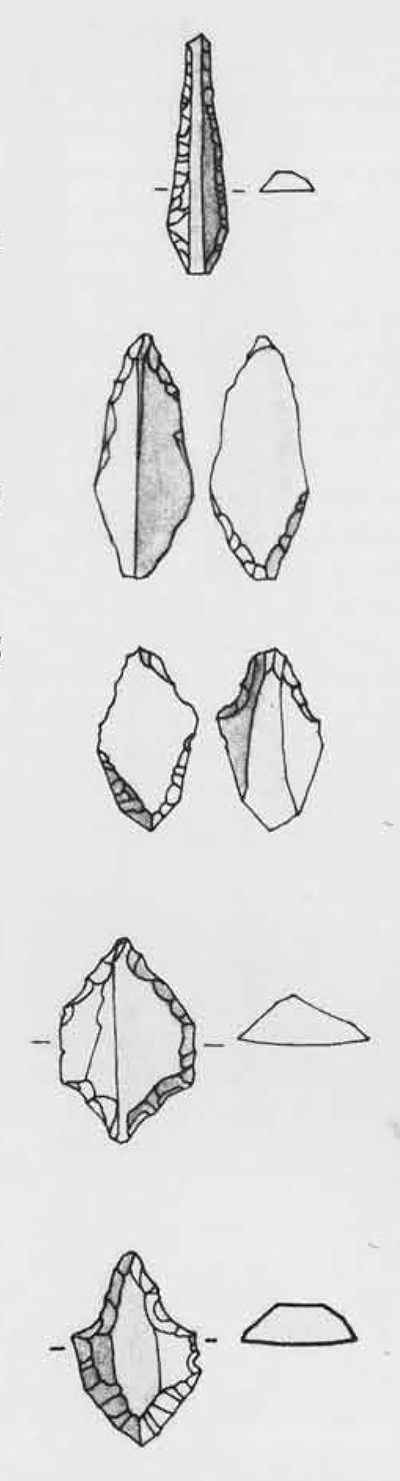

Typologically speaking, three main types can be observed, each of which shows slight variations due mainly to the position of the retouching.

The type most obviously used for drilling operations is a classical borer obtained from a flint microblade with double side-backed retouching on the working edge and proximal inverse retouching which produces the convergence of the edges towards the bulb. The latter is often removed so that the borer can be more easily fitted into a handle. The whole instrument is about 2 cm. long, of which about 1 cm. is accounted for by the borer itself.

The second type, which varies in size from 5-6 mm. to 1cm., is generally triangular in shape with a barely outlined distal borer between two retouched notches. As a rule, in this type also, the proximal part has inverse retouching on the two edges.

The third type, similar in shape and size to the second, differs from it by the presence of a rather steep, direct retouching along the two edges and the absence of proximal inverse retouching. The relatively high frequency of these features in a large number of implements indicates that it is not simply a variant of Type 2 but a deliberately produced shape which probably has slightly different functions.

Microscopic analysis of all these implements has revealed not only traces of wear on the points of the elongated Type 1 borers due to their rotation but also numerous patches of lapis lazuli powder adhering to the small retouch scars. In one case, microscopic traces of carnelian were found on the extremity of a Type 1 borer fragment.

So far, 69 implements of the more than 200 recovered have been found to bear traces of lapis lazuli. This proportion is rather significant if it is borne in mind that during flotation a large number of implements may have had the small traces of power adhering to their surfaces washed away by the water.

Analysis of the distribution of the lapis lazuli patches over the borers is still being carried out, and should enable us to identify the various uses to which these implements were put.

To date, the following constants have been found: on the Type 1 borers the lapis lazuli powder regularly covers the distal extremity and is often present over the whole length of the working part of the implement; on Types 2 and 3 the powder is concentrated mainly on both the side notches; in other cases, it is found on the two faces of the implement on a level with the notches themselves and the small borer; less frequently it is found on the borer point itself. The impression one has is that these implements were not intended to be used simply for drilling but were related to some of the preceding phases.

After the discovery of the lapis lazuli processing workshop at Shahr-i Sokhta and the identification of the function of the large number of borers found in it, we decided to subject to microscopic analysis the thousands of borers found during a survey carried out on the surface at Tepe Hissar by G. M. Bulgarelli, R. Biscione and M. Piperno in August 1972.

This material was coordinated with Erich Schmidt’s old grid which should make dating possible. Many of the implements, even after forty years’ exposure on the surface and in spite of our careful washing, still show traces of lapis lazuli powder and, in some case, of bitumen.

Study by Mr. Bulgarelli has shown that these implements were not made by the flaking technique used at Shahr-i Sokhta but mainly by burin blows. This would account for the presence of hundreds of burins at Tepe Hissar whereas they are extremely rare in the other 3rd millennium assemblages in eastern Iran. As part of his study, Mr. Bulgarelli has reconstructed the various working phases from burin to finished borer.

In considering Shahr-i Sokhta and Tepe Hissar we are thus dealing with a rather interesting phenomenon of functional convergence and technological divergence, whose explanation may be deduced from the exact locations where the material was found. At Hissar it was scattered all over the site, pointing to the existence of several small workshops, each of a few artisans. At Shahr-i Sokhta there was a single large production center, which seems to imply the presence of specialized artisans depending on a centralized authority controlling the internal demand and exportation.

The discoveries made at Tepe Hissar and Shahr-i Sokhta have made it necessary to reassess the lapis lazuli objects found at the excavated cities of protodynastic Mesopotamia. By courtesy of Dr. R. Barnett of the British Museum and Dr. R. H. Dyson, Jr., of the University Museum a thorough examination has been made of a good deal of the available material from the Royal Cemetery of Ur, which seems to correspond chronologically to Shahr-i Sokhta period II, where much of the lapis lazuli found is concentrated. The aim of the survey was two-fold:

a) to verify the presence of the same traces of working as those found on the lapis lazuli wasters in the Iranian centers;

b) to establish how the material was shipped from Badakshan to Mesopotamia, whether in the form of raw material, semi-finished or the finished product.

The incised and carved objects are culturally typical of the Sumerian tradition and have sufficient points in common with objects of other raw materials. Because of their geometrical simplicity, beads seemed the most suitable for typological analysis without the necessity of considering factors of an aesthetic or social nature.

Of the 45 types from the Royal Cemetery of Ur so far identified only three are repeated at Shahr-i Sokhta and Tepe Hissar: the plain surface cylindrical, spherical and discoidal types, the simplest and least typical types of the Royal Cemetery which abounds in biconical, barrel and axe shapes. There seem to be good grounds for concluding that most of the Ur beads were not made in eastern Iran.

What, then, is the explanation for the large quantity of lapis lazuli waste found at Hissar and Shahr-i Sokhta? The probable explanation is one of an exquisitely economic nature: the technology and production of rejects increased as a function of an increase in costs and speed of transport which gave rise to the necessity of freeing the lapis lazuli from all its impurities (more than 60% of the original mass). The elimination of worthless material reduced deadweight and allowed the semi-finished product to be sold at a higher price. It is possible to reconstruct an equation as follows: Total Price = cost of extraction + middlemen’s operations and profits + transport costs + processing costs + cost of commissions and taxes.

Thus the development at Tepe Hissar and Shahr-i Sokhta of workshops for semi-processing the raw material must imply that the saving in transportation costs to the final destination was measurably greater than the workshop costs.

An indirect confirmation of the fact that lapis lazuli was shipped from Iran to Mesopotamia in the form of small blocks or semi-processed masses comes from the finding of typical flaking furrows on necklace beads and bracelet elements and on mosaic tesserae. The latter are of particular interest as they were less carefully smoothed and polished than decorative objects.

By courtesy of Mr. F. Dungey, Chief Restorer at the Department of Western Asiatic Antiquities of the British Museum, we were able to examine a few tesserae of the central register of the war scene in the so-called “Standard of Ur” which was restored in March-April 1973. Four of the fifteen tesserae examined showed the typical furrows produced by flint blades.

Although only a beginning, this is a definite indication that the study of the relationship of mutual stimulation between two of Childe’s categories—technology and trade —is a valid approach for future research and anthropological analysis.

- Microlithic flint borers from Tepe Hissar, corresponding typologically with those from Shahr-i Sokhta.

- Flint drill from Shahr-i Sokhta (left) and one from Tepe Hissar. Note the close functional similarity in rather different tool-making traditions.

- Lapis lazuli cylinder seal of the third millennium B.C., one of the few complete lapis lazuli objects other than beads found at Shahr-i Sokhta.

- War scene from the mosaic standard of Ur, excavated by the Joint Expedition of the British Museum and the University Museum. About 2500 B.C. Photo courtesy of the British Museum Western Asiatic Department.

- Two lapis lazuli tesserae from the end of the stanard, showing the groove cut on the polished face resulting from the splitting blow. Photo courtesy of the British Museum Western Asiatic Department.