Tlingit ethnographic collections include large numbers of copper objects in many types, most of them made from the commercial copper of Europe. Early accounts from the trade in sea otter fur record that vast quantities of commercial metals were carried to the Tlingit by Russian and American ships. Indian tradition insists that copperworking was known in prehistoric times and that the metal had been brought from the interior. The Tlingit monopolized local commerce, serving as middlemen between the coast and the far interior in a trade reinforced by marriages of Tlingit men to Dene Indian women. It has been assumed, however, that the Tlingit source of native copper was through trade with the nearby Eyak and Ahtena Indians of the Copper River Basin to the north.

Earlier attempts to identify native copper among Tlingit metal objects have failed because the native metal is lost in a flood of trade material. However, Indians claimed that they could distinguish the valuable native metal from commercial substitutes by appearance. We have found that native copper can be distinguished at a glance if the original surfaces have not been painted, corroded, or destroyed by metal polish. This is a consequence of a specific Tlingit technology. The metal tools which we have studied also raise unexpected puzzles about the far range of Tlingit trade and travel on a scale not suggested by earlier literature.

Frances first noticed the significant features of the Tlingit daggers several years ago, when she was working on detailed descriptions of specimens being sent on loan to another museum. Apparently no one before had looked closely at the metal or had tried to identify the horn with which it was pommeled. After our marriage we began a joint attempt to work out some detailed knowledge of the technologies involved in her breakthrough. Our studies were supported by the School of Metallurgy and Materials Science of the University of Pennsylvania under National Science Foundation grant #GP4766. This work led us in many directions in the application of modern physics and chemistry to the elucidation of ancient crafts. Unfortunately, some parts of our report must deal with the highly technical ideas of physical science. We have been unable to translate these passages into a more literate idiom.

Dagger blades of native copper show a surprising blend of primitive and sophisticated metallurgical technique. The metal is soft, with no evidence of stress-hardening. Crystals are underformed, showing no hammering or annealing. There is little penetration of cuprous oxide into the metal, indicating that it has not been in a forge. The gross patterns of crystal structure are plainly visible on all undamaged surfaces, and tiny natural voids which were spaces in the original crystal mass are open and undeformed. We can reconstruct the technology by which these tools were made and finished from readily apparent details.

In working native copper, the Tlingit smith developed his metal as a mineralogical specimen, deliberately conserving its characteristic features. Dagger blades are trapezoidal in cross section, with the smaller obverse faces polished. Broad flat reverse faces show long longitudinal wiped grooves which were apparently conserved as tool-marks; they are the typical mark of a stone saw used in the hand to slice up metal. Thus each surface is a natural section of the copper mass, cut as we would cut it to study internal structure.

Museum Object Number(s): NA1287A / 42-30-42 / NA1288A

Sawing was the standard Tlingit method of stoneworking. Slabs of sandstone and cortex flakes from basalt cobbles were used to saw slate, granites, and jade. Thus Tlingit copperworking was a simple extension to metals of a stoneworking technique. Stone saws are extremely abundant in Tlingit archaeological sites. Unfortunately, only small samples from excavated series have been preserved in museum collections, and none of the specimens show any impacted metal or metallic corrosion.

Each dagger has a reinforcing rib of copper applied to the narrow top face of the trapezoidal blade. This is analogous to the stiffening ribs and channels of a steel girder in modem construction. These stiffening ribs were ground to fit very tightly to the blades, set in place with a number of tiny cylindrical pins fitted into drilled holes, and joined to the blade by a thin joint of commercial solder. The sweated-together solder joints are admirable in their tight, precise joins and in the thin film of solder; they meet the standards of an expert modern mechanic. Thus the dagger blades combine primitive and sophisticated metallurgical processes, native techniques with those of Europe.

Metals are notoriously subject to corrosion on the Northwest Coast, where the combination of a soggy climate and sea spray attacks many materials. Northwest Coast metals in museum collections show a remarkable resistance to corrosion, unless they have been scoured to bright metal, and then deterioration begins even under good storage conditions. Microscopic study of intact surfaces shows that an effective method of surface finish, which was both a stain for crystal structure and a corrosion-proofing, was known to the Tlingit.

None of the surfaces on steel and copper weapons from the Tlingit and Haida were originally finished bright. Indeed, a bright reflecting surface on a weapon is a fault anywhere in the world, and modern firearms are browned or blued to prevent the flash of reflected sunlight that may give the enemy a target. Browning and bluing of steels also produce corrosion-resistant surfaces. Tlingit metal-surfacing was likewise multipurpose.

Surfaces of Tlingit metal tools were chelated (a technical term, not yet a dictionary word) with fish-oil. Chelating agents are complex, long-chain organic carbohydrates with many double bonds in the carbon chain. These double bonds represent unsatisfied valences, and contribute to the instability of unsaturated organic molecules. When a chelating agent is applied to a cleaned metal surface, many valence bonds are established between cations at the raw metal surface and potential anions at double bonds in the organic molecule. The long organic molecule is thought of as becoming attached to the metal surface by many ‘claws’ (Latin chelae), forming a dense and chemically stable surface clutching the metal. Chelation films are somewhat comparable to paint films, but they are far harder and more durable, being chemically bonded into the structure of the metal. Our best modern chelation agents are tannin and fish oils, both used in modern industrial processes. The principle is a chemical discovery of the past decade.

Museum Object Number(s): NA1286A / 42-30-42

The Tlingit extracted and purified large quantities of fish oil to store as a winter foodstuff. They often used a dugout canoe as a boiling vessel into which heated cobblestones were put to cook out the oil. In villages where preparation and use of fish oil were routine, the metalworker was certain to get oil from his hands onto the surfaces of his work, and could observe the appearance of a durable surface finish that resembles the browning of steel gun barrels. Such selective staining of copper, with corrosion resistance of the stained surfaces, would quickly produce the process from the accident.

Native copper differs from smelter copper in two ways. Native copper is extremely pure, and it is made up of large crystals. Both purity and large crystal size can be produced in smelter copper by modern methods, but these techniques were not yet known in the nineteenth century. The crystalline structure of native copper is almost the same as that of smelter copper, but the crystals in smelter copper are minute. Both native and smelted metals are made up of a mass of dendritic twinned crystals. Some of the single twinned crystals in Tlingit daggers are almost a half inch in diameter; we have seen single crystals more than six inches in diameter in native copper from other sources. Smelter copper rarely has single crystals more than a thousandth of an inch in diameter. The smelted copper has been chilled from a melt in a fraction of a second, producing tiny crystals. Native copper has grown from solutions in cavities within basalt over an interval of many centuries or millennia, and we do not know what the upper limit of crystal size may be.

Museum Object Number(s): 42-30-42

Museum Object Number(s): NA4072

Phoebe A. Hearst Museum of Anthropology, University of California, Berkeley, Nos. 2-4695, 2-4696.

Metallic copper forms from a solution or from a melt by crystal growth. Incipient crystals, which are cubical in form, float in the solution. When they clump together, a corner of one cube becomes attached to the center of the square face of another crystal. The geometrical axes of in-contact crystals orientate themselves at the furthest possible angles from one another, as a result of repulsive and attractive electrical forces between the two crystals.

Dendritic (tree-like) clusters result. Individual crystals within the dendrite continue to grow, their molecular patterns interpenetrating one another in the manner called twinning, until the space available to their growth is filled or until the conditions of the solution no longer favor crystal growth. Whether the individual crystals are large or small, this dendritic pattern of orderly geometrical relationship between individual crystals is the structure of all copper that has not been hammered. Cast smelter copper has similar structure, but it is microscopic.

As a result of the geometrical relationship between twinned crystals, any cut surface on a plane through the dendritic mass will intersect crystals at two different orientations. The two types of cut surfaces show very slight differences in chemical behavior. They can be selectively etched and stained to develop a picture of the crystals and of their boundaries. This is the principle involved in modern preparation and study of metallographic sections, and it was also the principle exploited by the Tlingit coppersmith.

After learning to recognize native copper in Tlingit daggers, we began to find the same metal in other objects, all of them rare exceptions to the bulk of smelter copper in collections. We noted two conspicuous features that characterized smelted copper; its crystal size is microscopic, as already noted, and it includes many tiny bubble-holes, sometimes compressed to flat lens-shaped openings under the rolling mill. The native copper shows small natural openings, irregular voids left between growing masses of crystal, voids coated with copper minerals. We found that the smelter coppers were excessively impure when we studied their chemistry.

(Right) Shield-shaped Tlingit rattle of native copper representing a miniature tina or ‘chiefs copper.’ All of the detail is carved into the thick copper slab. Phoebe A. Hearst Museum of Anthropology No. 2-4805.

Many copper specimens had been cleaned again and again with abrasive metal polishes and acids, and their original surfaces have been destroyed. Since the total collections show so large a proportion of smelter copper, scoured specimens are not worth further study; chances are but one in a thousand that they might be native copper.

The commonest pieces of old Tlingit jewelry are massive bracelets or torques of copper, their ends carved into stylized heads of wolves or of ravens. Most of the hundreds of such ‘ingot copper’ bracelets that we have examined are either of cast trade metal or they have been so scoured by silver polish that their original surfaces have been lost. However, one pair of bracelets cut from bars of native copper has survived without mutilation.

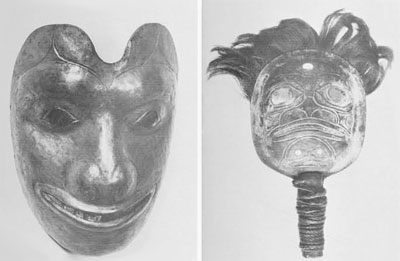

Several pieces made from sheets of native copper have been found. They have passed through at least one stage of hot-forging without destruction of their large crystals. Boundaries between crystals are depressed; the metal was apparently etched before chelation with fish oils. These specimens were shaped from large slabs of sawed-out copper which then took secondary shaping by hot-forging. One is a shield form rattle, the other a mask-shaped rattle.

In both cases the metal is more than an eighth of an inch thick. Its inner surfaces are irregular and marked by forging with stone hammers. These sheets were apparently somewhat thinned by hot-forging from sawed slabs. They were then shaped by hammering them into a hollowed wooden form. All of their detailed surfaces were done with carving knives and gouges.

(Right) Haida mask-shaped rattle of smelter copper, made in the same manner as the two rattles above. The many tiny black spots which show in the photo are bubble holes from water vapor caught in the molten metal as it chilled. Museum of the American Indian, Heye Foundation No. 1087.

Forging must have been minimal, because gross crystal structures are conserved, although flattened and distorted. Other specimens represent cutting-up and reuse of larger objects of native copper sheet. They suggest that far larger sheet-like artifacts of native copper exist, but they must be a minute part of the total collections.

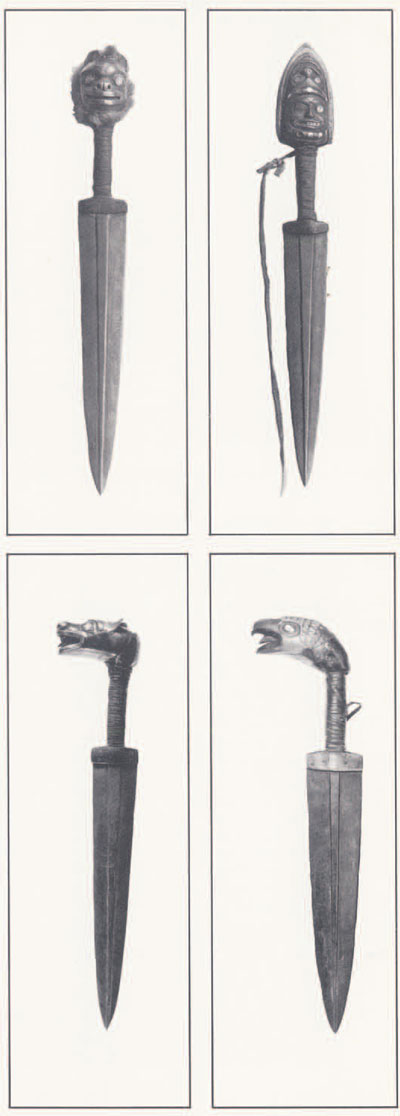

Exotic materials other than native copper were used by Tlingit artists. Pommels on seven daggers were carved from extremely heavy pieces of horn, which differs markedly from that of any of the sheep or chamois, and from that of any of the cattle or antelope. We wondered about the mythical unicorn! Some of the layers in the horn are black and dense, much is yellow with growth rings and included hair-like vessels that resemble wood, some is white and translucent like ox horn. Specimens were cut through several areas and zones of the horn; they include combinations and intergrades between the varieties.

Comparison of these carvings with several hundred musk-ox horns, including Central Eskimo specimens whole and cut, quickly indicated that musk-ox is the only mammal in which age variations and sexual differences provide large masses of horn which duplicate all of the variations in the Tlingit carvings.

The structures and growth-stages of musk-ox horn are more complex than those of any other ruminant. We have worked out their relationships in detail, but the history of this horn is a specialized chapter in zoology, too involved to summarize here. The main point is that the material can be identified with certainty if one recognizes its variety and complexity and if one has large comparative samples. It was a precious material to the Tlingit artist.

A large ladle in full ‘totem pole’ style has a bowl of mountain sheep horn and a handle assembled from ten pieces cut from a pair of musk-ox horns. Other musk-ox horn occurs in Tlingit collections. A small cylindrical box corresponds in every way to the boxes of the Central Eskimo, but it has been later incised with the symbolic emblems of the bear in Tlingit style. Still other exotic materials occur. The handle of one Tlingit steel knife, a Sheffield Bowie of the 1850’s, has been made with scales of bison horn.

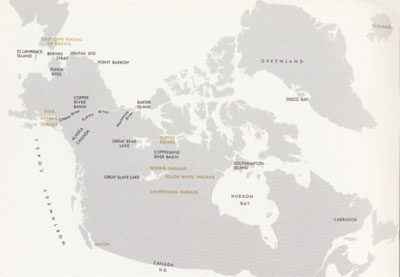

At least within historic times, musk-ox have not been seen west of the Coppermine River. Contrary reports have been based upon Pleistocene fossil specimens and upon fur robes brought back to Alaskan Eskimo villages on whaling ships. The only ethnographic specimens made from musk-ox horn which we have previously seen have come from the Central Eskimo and from the Dogrib Indians north of Great Slave Lake. Thus musk-ox horn is far more exotic to Tlingit than is native copper.

All authorities agree that the Tlingit obtained their copper from the Copper River Basin of Alaska. Pairing of copper with musk-ox horn also suggests a more remote source. We have therefore submitted some of our most valuable copper specimens to emission spectroscopy in attempts to find chemical trace elements that may relate materials to copper outcrops.

The results are surprising, and are reported in the following paragraph. The two Tlingit daggers differ from the copper of the Copper River Basin, containing a different trace element. They therefore came from another area. They differ more markedly from the copper of the Copper-mine River, a basin in which natives made extensive use of musk-ox horn. All that we can say at the present time is that the mine for Tlingit copper has not been located. Our best guess is that it is somewhere near Great Slave Lake, at the source from which the Chippewayan obtained the metal for their knives.

(top right) The pommel is carved into an emblem of the shark. Eyes, teeth, and other inlays are of abalone shell. The reverse is a thin sheet of trade copper which had been bezeled around the edges of the carving and secured to it with tiny copper nails of native manufacture. This pommel is of trade metal, the blade of native copper. The edges of this pommel are sharpened, as are many of the pommel daggers of steel. They are adapted to slashing an enemy on the backstroke when one has failed to stab or slash with the thrust of the weapon, after a common convention of swordsmanship.

(bottom right) This specimen is from a remade weapon in which a relic dealer joined an ancient pommel with a new blade of steel. The pommel, which shows the emblems of the raven, has abalone inlays, some of them replacements. The binding on the grip is modern Eskimo hair-seal rawhide. Museum of the Native American Indian, Heye Foundation No. 1/2425.

Museum Object Number(s): NA1287A / 42-30-42

Each of the three native copper industries shows a trace element pattern that excludes it from the other two groups. Tlingit copper contains a trace of lead. Coppermine River copper contains traces of aluminum, chromium, nickel, and molybdenum. All five of these elements are missing from the Copper River metal. That from the Copper River is the purest of the three groups, with less iron, magnesium, and silicon than the other two. All contained variable traces of silver. They represent three distinct and distinguishable geological sources. Only the Tlingit metal is of unknown source.

Northern North America must have many sources for native metals upon the basalts of its glacially-stripped landscape. Many different peoples have used these metals while still living within a stone-age world. We have therefore embarked upon a broader study of the native metallurgy of the Northwest Coast tribes, of the Dene Indians of the Interior, and of the Eskimo. In each case we are presented with an undescribed technology and an expert native use of rare natural resources. We should present our overall impressions of such technologies at the present stage of our study. All aspects need more work and more detailed description. All industries especially need field studies of quarries and workshops, with full analyses of tools and debris.

The most primitive metallurgy of the North was that of the Tlingit, in which native copper was sawed and ground into shape, as though it were a granite, by stone tools. However, at the earliest stage at which we can see this industry, it was interblended with the soldering and hot-work of European tinkers. It quickly led to a sophisticated industry in foreign metals, amply documented in every Northwest Coast collection.

The second-most primitive metallurgy of the North was that of one group of the Central Eskimo (the Copper Eskimo). These people shaped their copper tools by sawing and grinding, smoothing and polishing every surface. However, they sharpened and hardened their cutting edges by cold hammering. Their superb tools merit more extended discussion elsewhere.

The metallurgy of the Central Eskimo immediately plunges us into difficult problems concerning the technology of their eastern and western cousins, peoples of Greenland and of the Bering Strait. These were also metal-age people in prehistoric times, and we have only begun to study their technologies.

The natives of Greenland found three sources of iron in prehistoric times. It is possible, however, that trade iron from the Viking colonies of Greenland was the first metal known to these people, and that their exploitation of natural metallic resources was a consequence of contact with the Viking settlements. Nevertheless, the Greenland Eskimo exploited three sources for iron; meteorites, native iron from the basalts of Disco Bay, and iron spikes in driftwood. They apparently worked iron in the same way that the Central Eskimo worked native copper, by stone sawing, grinding, and cold-forging of edges. Their metallurgy raises difficult problems of tram-Atlantic contact for Eskimo technological models.

The Eskimo who have long occupied the shores of each side of Bering Strait represent our grand example of trans-Pacific contact. A single people have bridged the strait between Alaska and Siberia for at least two thousand years. To them, with their expert technology and excellent boats, the sea between America and Asia was a highway, not a barrier. Their metallurgy and art styles are central to all problems of Eskimo and Dene prehistory.

We have recently started to study the ivory carvings and the carving tools from the Bering Strait peoples, ethnographic and archaeological. In each successive art style and regional stratigraphy, we are looking at tool marks and at the tools which produced such marks. We have been amazed to discover that Eskimo technology in this area has been based upon steel tools since the time of Christ. The history of this Eskimo art sequence is the history of a Siberian steel-age technology.

All of the famous carved ivories from the Old Bering Sea Style, Ipiutak, Punuk, and other old cultures of the Strait show distinctive marks of steel cutting edges. These cutting edges were hook-shaped burins, adze blades with extremely acute edge-angles, crooked knives, and perfectly cylindrical drill-bits. None of the distinctive tool marks could have been made by stone. We have labored long, without success, to find the use-marks of stone cutting edges on old ivory carvings from the Strait.

A few steel tool edges, deeply corroded, have been excavated from sites on the Strait. Chemical analyses have demonstrated that these cutting edges were carburized furnace steels, not meteorite, native iron, or soft iron. They were the product of Siberian or Chinese metallurgical centers. Typologically, these ancient tool edges are like the steel edges of nineteenth century Eskimo tools.

The ivory-carver’s art from the old cultures of the Bering Strait presents us with some serious problems in intercontinental relationships of cultures. The crafts are based upon Asiatic steel. The oldest designs, of the first century A.D., are concentric ellipses with cylindrical drill holes for inlays of rare materials, in the carvings of the Old Bering Sea Style. The next stage is one of burin-cut outlines, and carvings in the round, of distorted animal figures in postures of crisis, rather like Scythian styles from the steppes of Eurasia. Everything is cut with steel tools, at each interval during the past two thousand years.

The Bering Strait has always been the great bridge between the Old World and the New. From Paleolithic mammoth-hunter to modern Eskimo on Saint Lawrence Island, humans have lived on the great bridge between two worlds. This bridge is a core-area for future studies of metallurgy in American culture history.

Prior to 1870, when native patterns of social organization began to decay, Eskimo from Point Barrow went eastward to Barter Island to meet and trade with Central Eskimo. Men from the West carried steel to trade for copper with men from the East. Similar patterns of coastal trade across the Arctic prevailed in other areas; Copper-mine River copper was carried to Greenland in exchange for iron from the eastern Eskimo. Perhaps all of this activity centered upon more advanced cultures in Siberia; perhaps it was all organized upon the ancient mobility of the peoples of the American North and their technological flexibility. These are problems for the future.

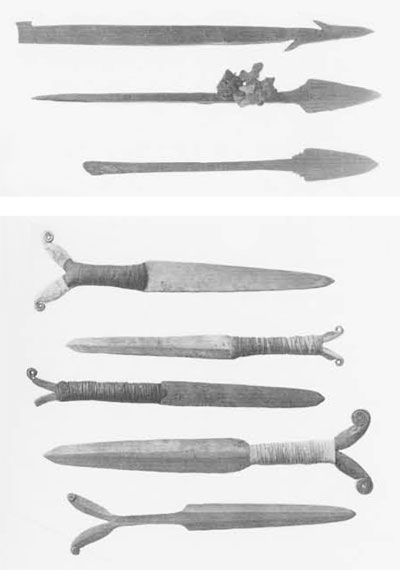

At any rate, the Dene, the Athabascan-speaking peoples of the barren spruce-forest interior, give us real problems. Their use of copper was the most advanced metallurgy of the North. We can see no links between their techniques and those of the iron-using peoples. They were operating in a full Chalcolithic (using copper instead of stone) technology. Every copper piece of theirs that we examine is delicate, thin, and light. The metal has been greatly modified from its native state, highly forged, with frequent welds and forging folds. It is entirely unlike the stone-age technology of the Tlingit and Central Eskimo, entirely unlike the trade tools of the Bering Strait people. It shows a full Chalcolithic technology, not one derivative from the Stone Age or from the Steel Age.

(bottom)Five Dene daggers from the interior of Alaska and British Columbia. All are of native copper which has gone through a forge and a charcoal bed, and which has been so reworked from native metal under the forge and the hammer-and-anvil that they show little trace of their original structure. They are light and delicate, the product of a sophisticated industry in native metals.

Museum Object Number(s): 35-27-3 / 30-25-267 / NA4020 / NA5786A / NA1237

Steel tools, made by Dene mainly from files, had replaced copper daggers before 1850. They show equal control of the forge and of the hammer. We are, however, more interested in the knives made from native copper, although steel daggers show the same technology. Dene daggers, in copper and steel, show both heat treatment and stress hardening as methods for controlling strength and edge-hardness of tools. Dene copper arrowtips, awls, and other tools show an equally expert technology. Study of the metalworking of the Dene promises a breakthrough into the real technology of a people who have been called one of the most primitive Indian groups in the Americas. Their use of metals was nevertheless the most sophisticated that we have seen in North America. Their crafts require deeper study, as does their everyday life.

It is now apparent that, in northern North America, we are dealing with the archaeology and ethnology of metal-age peoples, peoples who were more part of the culture history of Eurasia than they were of the New World. The archaeological metallurgy of the North is now seen to be an unknown quantity. Communication over vast areas, primary craft dependence upon metals, and technological sophistication were all features of the American Arctic in late prehistoric times. It appears that the history of ‘the great Dene race’ may be central to all of these problems. Dene metallurgy was the most expert in the North, and Dene metallurgy now seems central to Athabascan culture history; where did the Dene and their metallurgy originate? Were the Dene recent immigrants from Asia?

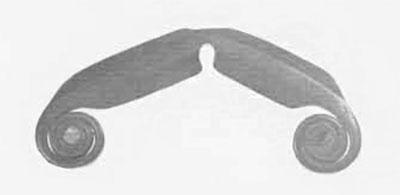

Dene daggers are invariably pommeled with a pair of tight spirals, the whole knife being made from a single piece of metal. The spirals had also been forged to shape, but they had been highly smoothed by grinding before they were twisted and they show no forging-marks. Outer edges of the spirals arc rounded and worn from use; the pommel edges appear to have been used as a tool to separate hide from carcass in skinning game.

Although the double-spiral motif of the Dene suggests the double-curve design of the eastern Algonkian peoples, it has no exact counterpart in North American art except in Tlingit. It has many parallels in the art of north China and Siberia. Among the Tlingit, it does not occur on any of the daggers. Rather, it was part of a poorly-known hair ornament made of copper or iron. One specimen was made of native copper, another of commercial Sheffield plate. The latter must have been the work of a European smith, for it was shaped between the hammer and a steel mold (a swaging block). Its surface was then engraved with a European vine-and-leaf design. This early variety of Sheffield plate, with a thick soldered-on layer of silver applied to thick copper, was probably made in England between 1790 and 1810.

One is tempted to think of the Tlingit hair ornaments as originating as trophies broken from Dene daggers. However, every hair ornament that we have seen has the spirals coiled in the opposite direction to those on the Dene knives. The direction of coil in each group is so consistent that it must have been a fixed part of each artifact type. The native symbolic meanings of the double spirals have not been recorded.

Dene daggers, throughout their known area of distribution, represent a single highly stereotyped artifact type, a perfected functional form. Their culture history is entirely unknown. On the other hand, the Tlingit dagger of native copper was an uncommon type, coexisting with at least three other major types of steel daggers in native styles. Its blade is an enlarged copy of the Dene dagger. The other types show little resemblance to Dene forms. The Tlingit forms are obviously all simple weapons, poorly adapted to any purpose more worthwhile than fighting. Tlingit weapons were luxury items that evolved as part of the affluence of Northwest Coast cultures. Dene daggers were primarily the tools of hunters and trappers, their role as weapons being quite secondary.

Use of native metals in the technologies of the American North cannot yet be put into proper perspective. As we learn more about the archaeology, we have many glimpses of ancient sporadic work in metals over a huge region, from Bering Strait to Greenland and Labrador, from the state of Washington to Quebec. There is too little data to permit reconstruction of the most elementary history of these technologies. At the same time, we are beginning to glimpse intimate contact between the Alaskan Eskimo and the peoples of Siberia, and the long dependency of Western Eskimo technology upon the metallurgy of interior Asia. Metal tools of the Tlingit, the Dene, and the Eskimo are only the surface of complex problems in culture history, a surface which we cannot see through.

Northern men today greet strangers with a handshake, but they have heard of older conventions. Formerly, they say, strangers extended their left hands while holding their knives in their right. In 1824, the British explorer Captain G. F. Lyons sailed into Hudson Bay and made the first recorded European contact with the isolated Eskimo of Southampton Island. They came to greet him holding a gift in one hand, a stone-bladed knife in the other. This ambiguous convention of introduction seems to have formerly been universal. Some Eskimo followed this with a formal duel at boxing, wrestling, arm wrestling, or even knife fighting between champions. These social conventions must have been erected upon a long history of culture contact over vast regions among many diverse peoples. Trade goods and knowledge of technological processes traveled great distances through such contact.

Many of the culture history problems of the northland can only be glimpsed through such sidelights. The actual problems are still to be phrased. Technological studies of ethnographic and archaeological complexes must be greatly extended before the major problems can be defined.

However, our initial study of a single Tlingit dagger type has led our thought in several directions. Tlingit trade with the interior was far more extensive than we had realized, reaching east of the Coppermine River and touching mines which we cannot yet identify. The Dene trading partners of the Tlingit, who have been considered peoples with simplistic technologies and a slight cultural heritage, appear in a new light as the carriers of a peculiar metal-age technology. Whatever the richness of their culture and technology may have been, it has been lost in a recent sink of depopulation and of cultural truncation. Dene archaeology and ethnology demand reexamination, even at this late date, for it is obvious that some of our literature is myth more than fact. A single copper knife in any Dene collection raises problems inconsistent with the stereotyped phrases of the literature.

Western Dene problems arc difficult. We know from native tradition, place-names, and archaeology that the Tlingit have been moving northward in the last three centuries, pinching off a Dene corridor to the sea along the Copper River of Alaska. The Eyak and the Ahtena are now squeezed back to the very valley of the lower Copper River, whereas they formerly held a broad area south and north of it. Their daggers were identical with those of interior Dene bands, suggesting that they shared a detailed technology with the Dene peoples of northeastern Alaska, the Yukon, the Mackenzie, and the basins of Bear Lake and Slave Lake. Tlingit military expansion from the south and Russian expansion of Aleut slave-communities from the north have pushed the Eyak out of most of their earlier coastal habitat. The Denc corridor to the sea has been almost cut.

The near-identity of Eyak-Ahtena industries with those of the far interior suggests that both groups constituted a single people or ‘nation.’ Linguistics indicate that the Tlingit speak a remotely related tongue, separate and divergent for three millennia from northern Dene speech. The relative uniformity and lack of strong dialectal boundaries within the northern Dene language suggest recent divergence or continuous culture contact within a single people. Interior forest tribes of the Northwest thus show little local specialization in their languages or in their crafts. The order of diversity among them apparently has a time depth of less than fifteen hundred years in language, even less in their arts of life. Some of this is doubtless a factor of continuous intercommunication, some of it must be a factor of the recency of their common origin.