Aboriginal Quimbaya goldsmiths in the Cauca Valley of Colombia were turning out remarkable hollow gold castings long before the birth of Cellini in 1500. Any attempt to compare the artistic merits of their creations with those attributed to the great Florentine would prove nothing beyond the fact that tastes differ. However, when it comes to mastery of basic technology with rudimentary equipment, these forgotten indigenous craftsmen do not have to yield precedence to anyone. Paul Bergsöe, one of the bare handful of experienced metallurgists who have concerned themselves with ancient metalwork of the New World, has echoed the lay reaction of the sixteenth century Spanish conquistadores, observing that in Colombia “the excellence of the technique employed in casting is amazing.”

Museum Object Number:

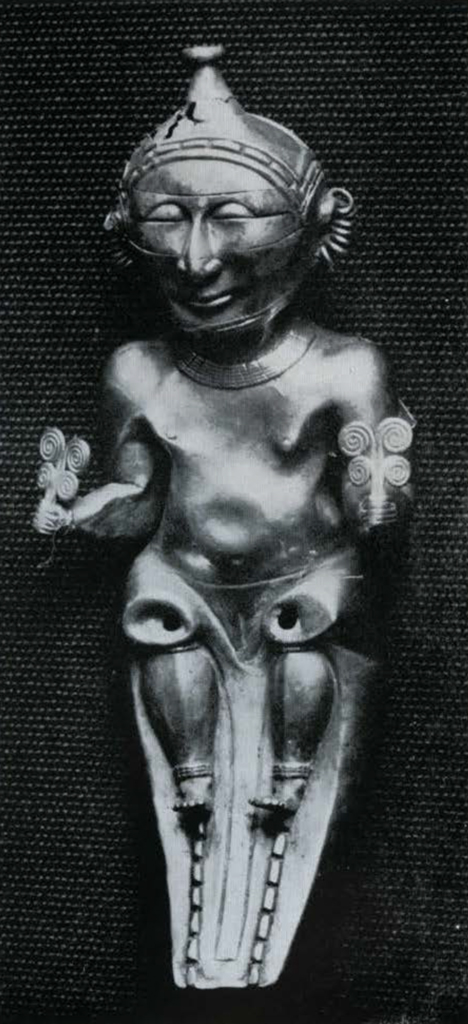

In 1920 the University Museum had the great good fortune to acquire two hollow cast Quimbaya figures that Farabee has understandably called “real works of art” (Figs. 1 and 2). An almost identical, but slightly larger, figure seated on a similar elongated and gently curved duho or seat may be seen in the Archaeological Museum in Madrid. That piece and four other hollow cast effigies are part of the famous “Treasure of the Quimbayas” given to Maria Christina of Spain in 1892. The only other apparently complete figure of this type is a seated one owned by the Peabody Museum of Harvard University (Pál Kelemen, Medieval American Art [New York, 1946] Vol. II, Plate 218 c). It is generally similar to the two in Philadelphia, but about two-thirds as large.

As one looks at these striking pieces, it is only natural to wonder how they were made. The quick, easy and not very informative answer is by the cire perdue process, but someone who is not familiar with that process is likely to insist on having details and reasons. Briefly, the caster makes an exact model in wax of the piece he wishes to cast. This model is covered with an outer shell or mold of clay, in which a hole is left. After the shell hardens the wax is melted out through the hole, leaving a cavity of the same size and shape as the model. Molten metal is poured in through the same hole to fill the cavity; and when the metal has cooled the outer shell is broken off, revealing a perfect reproduction of the wax model in solid metal. For hollow castings the wax must be modeled over a clay core, which is removed after the piece has been cast.

Museum Object Number: SA2752

All descriptions of the cire perdue process of making hollow castings, as practiced in the New World before Columbus, seem to stem back to a technically inadequate translation of a sixteenth century account written by Friar Bernardino de Sahagun. For some sixty years this Spanish friar made an intensive study of customs, religion, and daily life in Aztec Mexico. His report on gold-working techniques was a phonetic transliteration in Nahuatl, the language of the Aztecs. By a sort of linguistic Tinker to Evers to Chance, this original version was translated into French by a German in 1890, and from French into English by an American in 1920. The French and English versions have each served as the basis for translations into Spanish. In this country the fashion in academic circles has been to paraphrase one of these successive translations or quote the English version in extenso, and let it go at that.

Seler’s French translation, upon which the whole impressive bibliographical edifice has been built, simply does not do justice to Friar Sahagun, however great it may be as a trail-blazing linguistic study. It is such a literal rendering that at times it makes little or no sense from a metalworking standpoint. The good friar and his Indian informants did a far better job of technical reporting than is generally believed and, once the characteristic Aztec prolixity and repetition are eliminated, his factual presentation of the successive steps in the process and the materials used is astonishingly accurate even in terms of modem practice. Trying to read the original with Nahuatl grammars and vocabularies–and generous help from Drs. Anderson and Dibble–was more entertaining and considerably more rewarding than doing a cross-word puzzle.

Having regard not only for what Sahagun wrote, but also for the mute evidence of surviving pieces and general technical principles, we offer the following highly condensed version of Sahagun with explanatory remarks:

- First they took charcoal and ground it well until it was pulverized. The powdered charcoal was then mixed with a little potter’s clay, and kneaded in the same manner as dough for tortillas. According to present-day metallurgists the core for a hollow casting must have certain physical characteristics: (a) “green strength” to retain its shape before it dries out and sets, (b) “hot strength” to stand the intense heat of the molten metal without changing shape, (c) enough elasticity to allow for normal shrinkage of the metal during cooling without cracking the casting, (d) porosity to take up gases formed when the metal is poured into the mold, and (e) a friable texture to facilitate its removal from the finished casting. The mixture of potter’s clay and finely powdered charcoal described by Sahagun satisfies every one of these requirements, the charcoal being added to give porosity, elasticity and a friable texture. Analyses of core fragments still found inside pieces from Colombia have confirmed that the same mixture, sometimes with sand added, was used there. Cellini used bone meal instead of charcoal and some casters use sawdust for the same purpose.

- After the clay and charcoal were thoroughly mixed they were modeled into convenient forms (i.e., roughly approximating the inside shape of the finished casting). These were arranged in the sun in the same manner as adobes, and allowed to dry out and harden for two days. It was absolutely imperative that the core be completely dry, for there is grave danger of an explosion if any moisture is present when the molten metal is poured at temperatures ranging from just under 900° to over 1,000° Centigrade, depending upon the composition of the gold alloy used.

- Further shaping and modeling of the core to give it the initial aspect of the piece to be cast was done with a small copper blade, and when the core was ready it was covered with a thin even coating of strained beeswax mixed with a copal resin to make it firmer. The wax coating was of the same thickness as the piece to be cast, and had to be uniform to avoid unequal cooling and shrinking of the metal which might have resulted in a cracked or defective casting. Surviving objects show that, using threads and little pellets of wax for decorative details in the same way a sculptor uses modeling clay and working with very sharp modeling tools, the ancient goldworker fashioned an exact positive image in wax of what he expected to come out of the mold after the metal was poured and had cooled; for the cavity left between the core and the outer shell when the wax was melted out would all be filled later by the molten metal. The great virtue of this process, as Sahagun intimates, is that wax is easy to model, and the wax pattern can be removed from the mold without taking the latter apart. Also the reproduction obtained in metal is such a faithful copy of the wax pattern that further tooling of the casting is seldom required. In fact, some gold castings found in Colombia are said to have had finger-prints impressed on the surface where some careless worker had inadvertently pressed the wax too hard. This gave rise to a belief among the gullible Spanish conquistadores that the Indians had some secret process to make gold soft and workable like clay.

- The wax model was then transfixed by small wooden pegs or thorns like maguey spines [which later served to hold and support the core]. In Seler’s translation, and everything copied from it, the function of these pegs has been misinterpreted. The Nahuatl verb used by Sahagun literally means “to fasten or hold together” so Seler, who was apparently more interested in a literal translation than in technical accuracy, jumped to the erroneous conclusion that the wax was thus affixed to the core. Nothing was needed to make the wax adhere to the relatively coarse surface of the core, but something certainly was needed to keep the core from slipping out of position after the wax was melted out and before it was replaced by the molten metal. This was accomplished by the pegs or thorns which penetrated the core and projected above the surface of the wax. When the wax model was later enveloped in the outer shell, the projecting ends of these pegs or thorns were embedded in the shell forming a series of minute bridges between it and the core. Today core-supports are made from wire having a much higher melting point than the metal to be cast, but the pre-Columbian goldworkers having no such wire, had to make do with wooden pegs. Messrs. Kennedy and Maryon have stated in personal letters that there is no technical objection to using green wood; it is quite tough, and the small pegs were exposed to very little of the molten metal, which began to “freeze” immediately upon being poured, so they merely became charred but did not bum nor disintegrate.

- Then the “pour” and entrance channels through which the molten metal would be introduced into the mold were made of wax and attached to the model. In the interest of strict technical accuracy we have departed from Sahagún’s chronological sequence to move this step up to its proper position in the process. The only defect in Sahagun’s report, which Dr. Anderson has confirmed, is that he sometimes departs from precise chronological order.

The location of the “pour” was dictated by two considerations: it had to be at the highest point of the model when the mold was in position to receive the molten metal, and preferably in a spot on the back of the piece to be cast where it would not show. In addition to the “pour” it was generally necessary to leave some way for air to escape from the mold cavity during the pouring operation. Otherwise the air in the lower part of the mold would back up under the pressure from the incoming metal and form bubbles in the casting or, if pressure became high enough, an “air-lock” would develop preventing the flow of the metal and resulting in a defective casting. Air vents, like the “pour” and other parts of the mold that were eventually to be hollow, were made of wax before the outer shell was applied. This was done by attaching small rods to the model where air was likely to be trapped. These would lead through the outer shell to its surface; and had to be so made that the exit hole would be higher than the “pour” when the mold was set in position to receive the molten metal. If the air outlets were not higher, the metal might pass right through the mold and run out of them before the mold was filled. As it was, the gold would flow part-way into them, forming tiny bars that had to be cut off later. The addition of the air vents is the only step in the entire process not specifically mentioned by Sahagun. However, we have found definite evidence of the use of air vents on one unfinished piece, and they must be presumed to have been used on complex pieces even though their existence has been obliterated by burnishing and polishing. The core-supports, “pour” and air vents having been placed, the goldworker was ready to “face” the model and apply the outer shell to complete the mold. - A thin coating of paste made of finely powdered charcoal and water was applied carefully to the entire surface of the wax model. The word used by Sahagún is literally “charcoal water.” Curiously enough, although Seler gives “eau de charbon” in his notes, he rejects it in favor of “charbon pulverisé” in the text, and Saville translated only the text into English. Dry powdered charcoal would have been less satisfactory on two counts: it would not have reached and filled the minute interstices as well, and it would have been more difficult to keep in place. This procedure of “facing” a wax model with an emulsion of carbon (graphite) is followed today in making fine precision castings, for without a thin protective coating of this sort the outer surface of the finished casting would be rough and pitted as a result of being in direct contact with the coarse outer shell.

- After the facing dried the entire work was enveloped in an outer shell made of clay and coarsely ground charcoal, leaving an opening for the “pour” [and also openings for the air vents]. Then it was put out in the sun for two days to dry thoroughly and become firm.

- When the mold had dried out in the sun it was placed in the fire to melt out the wax model inside, then packed in sand, and allowed to cool. Sahagun is technically accurate, for, contrary to the statements of some careless writers, the metal cannot be poured without first melting out the wax, because the intense heat of the molten metal would cause the wax to volitalize before it could escape, and the result would be disastrous. In a personal letter Mr. Maryon has noted that the sand would protect the hot mold from sudden draughts of cool air which might cause it to crack. So far as we know tongs were not used by pre-Columbian metalworkers, and it is probable that hot molds and crucibles were handled with lifting sticks or bent withies.

- The mold was then placed in a fire pot [and probably packed again in sand to hold it steady], and the gold was melted in a clay crucible or ladle. When the gold had melted it was poured into the entrance channel in the mold from where it flowed and spread out to fill the cavity in the interior. According to the illustrations in the codices, Sahagún’s “fire pot” was a refractory clay brazier heated by a charcoal or wood fire. Molds are generally pre-heated to facilitate the flow of the molten metal and assure that it will fill the mold cavity. Otherwise a defective casting may result from a “misrun,” the metal solidifying before the mold is completely filled. To quicken the flame the Indian goldworker used a blow-pipe, illustrations of which also appear in the codices and other early accounts. Refractory clay crucibles have been found in Colombia, and a well-known example in the Bendix Koppel collection is illustrated in Max Uhle’s Kultur und lndustrie Südamerikanischer Völker nach den im Besitze des Museums für Völkerkunde zu Leipzig (Berlin, 1889) Vol. I, Plate 4, No. I.

After the mold had cooled the outer shell was broken off carefully so as not to injure any fine details or projecting parts of the casting. There were tiny bars of gold where the air vents Jed from the surface of the casting, as well as a more sizeable gold bar where the pour was made. These had to be cut off and burnished down. - The piece was burnished with a burnishing stone. These were probably water worn pebbles. One found in the Chiriqui region is illustrated in George Grant MacCurdy’s em>A Study of Chiriquian Antiquities (New Haven, 1911) Fig. 33.

Occasionally some of the details had to be sharpened or touched up with a chasing tool, but the facsimile in metal of the wax original was usually so exact that this was not necessary. The core, of course, had to be removed by breaking it up and picking it out through open places in the casting such as the neck of the piece, the holes left by the core-supports, and frequently through larger openings intentionally left and later closed by soldering in patches of the same metal. - After it was burnished it was treated in an alum bath, heated again in the fire and bathed, and treated with gold medicine. Likewise it was rubbed with a mixture of wet clay and salt. These gave it a golden color. It was then given a final polish, and the work was finished. The ancient gold castings in the New World were generally made from alloys containing varying percentages of gold and copper, and sometimes small amounts of silver. Alloys containing copper get a thin scale of copper oxide on the surface when heated in the open air. However, by reheating the finished casting and treating it chemically in a mild acid bath or “pickle,” the scale of copper oxide, as well as some of the unoxidized copper on the surface, can be dissolved without affecting the gold. The more often this procedure is repeated, the more surface copper is removed until the object comes to have an almost pure gold surface. In ancient Colombia the early chroniclers reported that the Indians used a liquid or a mash made from plants containing oxalic acid for this purpose. As a mild acid is necessary, Sahaún’s “gold medicine” was undoubtedly some organic acid derived from plants or fruit juices. In this connection, Dr. Anderson has written us that the Aztec word “patli” has some parallels in the terminology of herbal medicine in pre-Conquest Mexico. According to Mr. Maryon of the British Museum gold alloys are still “colored” by bathing them in dilute nitric acid followed by a salt and alum mixture similar to that mentioned by Sahagún. This procedure is not to be confused with gilding or plating where additional gold is applied to the surface. What was done here was to remove base metal in the alloy from the surface leaving a higher concentration of gold there. Obviously this would not work unless the piece contained some gold to start with. For the final polish there is reason to believe that the Indian goldworkers used leaves containing silicon and pieces of split bamboo, which also contains silicon. Sahagun makes no mention of bamboo in connection with polishing goldwork, but be does refer to it in another report as a polishing agent for jade and other hard gem stones. If the lapidaries had discovered this use of split bamboo, presumably their goldsmith colleagues were not far behind. One expert on ancient metals of the Old World, who had never heard of Sahagun and was unfamiliar with pre-Columbian goldwork, told us recently that he had used bamboo slivers for a very delicate cleaning job on some Merovingian gold-this “rediscovery” at least five centuries after the Indian craftsmen had discovered the procedure empirically.

Although Sahagun’s account deals only with the technique of the Aztec goldworkers, the University Museum’s two figures from Colombia show conclusively that they were made by the same basic process with some elaborations. This is not surprising, since it is generally accepted that the technique was first developed in Colombia and imported into Mexico at a later date, probably from Panama or Costa Rica.

Each piece shows the characteristic rough cast surface inside the neck of the vessel where the core was not “faced,” while the outer surface of each is relatively smooth due to the wax model’s having been coated with charcoal paste before the outer shell of the mold was applied.

The face on the piece in Figure 2 was probably intended to show tatooing or body paint. For that purpose the artist made fine incisions in the wax model with a very sharp blade. However, due to incising too deeply and the unequal rate of cooling between the very thin metal at the base of the incisions and that in the rest of the face, these incised lines developed cracks. On the left side of the jaw the contraction of the metal over the core in cooling literally tore the piece along the incised line, leaving a crack with jagged edges where the contraction was sufficient to pull the metal apart.

Each figure bears unmistakable evidence of the use of wooden core-supports. In the piece in Figure 1 five core-supports were used: one through the top of each shoulder, two through the upper part of the buttocks, and one through the base of the curved seat. The boles which these core-supports left in the casting were carefully plugged with little discs of what appears to be the same metal as that used to cast the piece (Figs. 3, 4, 5, and 6). Only four core-supports appear to have been used in the piece in Figure 2: one through the top of each shoulder and one through each knee. Here the holes were either not plugged or have lost their plugs (Figs. 2 and 7). The damage to the knees would have dislodged any plugs that might have been there.

These figures show some departure from the technique as described by Sahagún in that they were not cast in a single piece. In Figure 1 the forearms and the hands with their spiral ornaments were added later. The forearms appear to have been shaped out of flat sheets of metal, and then soldered onto the piece. On the under side of the forearm there is a T-shaped soldered joint where the sheet was formed into a cylinder and soldered onto the upper arm, and at the elbow on the outside one may feel the joint which has been so carefully burnished and polished as not to be readily visible. Each hand with its spiral ornament was cast separately and soldered on, the bracelet effectively covering the joint. On this piece a large rectangular opening, probably to facilitate removal of the core, was left on the front of the curved seat. This bole was bounded on the top by a line connecting the anklets, and on the other three sides by the beaded decoration. This was done by carefully cutting out the wax before the facing and outer shell of the mold were applied. (It should be mentioned that where the wax was removed the core was in direct contact with the outer shell, which provided additional support for the core.) Probably the wax removed was used as the pattern to cast the patch that was later soldered on to cover the hole left by its removal from the model. The soldered joint for the patch and some traces of solder are visible under the beading, which was cast separately and applied later. The joint at the top of the patch, although burnished down and highly polished, is still visible between the ankles in Figure 1. The feet were cast separately and soldered on after the large patch, the anklets serving incidentally to cover the joint.

A similar hole apparently was left on the front of the piece in Figure 2, which was later patched in the same manner. On that piece the arms appear to be part of the original casting, only the hands with the decorative spirals being cast separately and later soldered on at the wrists. Here again the bracelet serves to cover the joint.

On general principles it is believed that, for casting, the molds for these figures were set at a 45° angle with the head and face down, the “pour” being located at the base of each piece. In that position the facial features and the front of the piece would receive metal free from any inclusions, bubbles or impurities-these would tend to rise and go to the back of the casting. Some confirmation for this belief is to be found in a small indented spot on the back of the ring around the opening on top of the head in Figure I, which in all probability is where one of the air vents was located. In removing the tiny bar of metal which was there when the piece first came out of the mold, the goldworker did not do a careful job. Also in Figure 6 there are holes on either side of the base, one of which has a square plug probably added in modem times. The metal here is very thin, and these holes were probably due to an accident in removing the excess metal in two branches of the “pour” located there. All traces of other air vents and other branches of the “pour” have been obliterated, but there undoubtedly were others on pieces of this size and complexity.

No analysis of the alloys used in either of these pieces has been made, but unquestionably they contain some copper, for small inclusions of copper salts are visible here and there on the surface under magnification.

Anyone who has read this far will realize that these exceptional figures show complete mastery of a difficult and involved technique that must have been developed gradually over a long period of trial and error. They are not only a vindication and confirmation of Sahagun, if any were needed, but lasting monuments to the skill and dexterity of a forgotten group of aboriginal craftsmen who could hold their own with the best we have to offer today in jewelry casting.

BIBLIOGRAPHY

EASBY, DUDLEY T., JR. Ancient American Goldsmiths, Natural History (New York, 1956) Vol. LXV, No. 8, pp. 406, 407-408.

MARYON, H ERBERT. Metalwork and Enamelling (Third Edition, London, 1954) pp. 200-223, 258.

MARYON, H., and P LENDERLEITH, H. J. Fine Metal-Work, in A History of Technology (Oxford, 1954) Vol. I, pp. 625-634.

PEREZ DE BARRADAS, JOSÉ. Les Indiens de l’Eldorado (Paris, 1955) pp. 150-15 l.

RIVET, P., and ARSANDAUX, H. La Metallurgie en Amerique précolombienne, Travaux et Memoires de l’Institut d’Ethnologie (Paris, 1946) Vol. 39, pp. 124-131.

SAVILLE, MARSHALL H . The Goldsmith’s Art in Ancient Mexico, Indian Notes and Monographs (Heye Foundation, New York, 1920) pp. 125-142.

SELER, EDUARD. L’Orfévrerie des anciens Mexicains . . . , VIII Congrés International des Americanistes, 1890 (Paris, l 892) pp. 402-418.

ZERDA, LIBORIO. El Dorado, l 883 (Ed. CAHUR, Bogotá, 1948) pp. 39-42, 47-49, 133-134, Fig. 35.

* We wish to thank the Director of the Museum, Dr. Rainey, for allowing us to examine and photograph the objects illustrated; Mr. Richard R. Kennedy, Chief of the Metals Laboratory at Wright Field, Mr. Herbert Maryon of the Research Laboratory of the British Museum, and Professor José Pérez de Barradas of the University of Madrid for technical advice; and Drs. Arthur J. O. Anderson of the Museum of New Mexico and Charles E. Dibble of the University of Utah for their kindness in preparing a tentative version of Chapter 16, Book IX of Sahagún’s Florentine Codex on the Aztec goldsmiths, and their assistance in explaining some of the mysteries of Nahuatl syntax and grammar. ↪